In the world of manufacturing, automation, and countless other industries, power transmission is fundamental. While electric motors are the driving force behind most systems, it's rarely the motor alone that delivers the desired power and control. Enter gear motors – a seemingly simple combination that plays a crucial, often unsung, role in modern technology. This article will delve into the principles behind gear motors, exploring their significance, applications, and future potential, particularly within the context of the ongoing shift towards increased automation and efficiency.

Understanding Gear Motor Basics: Bridging Speed and Torque

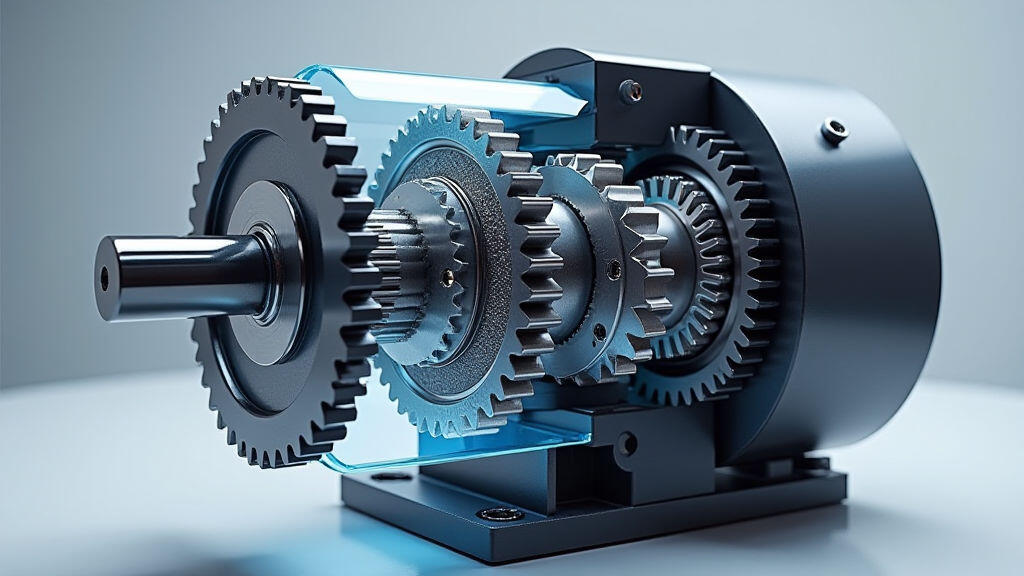

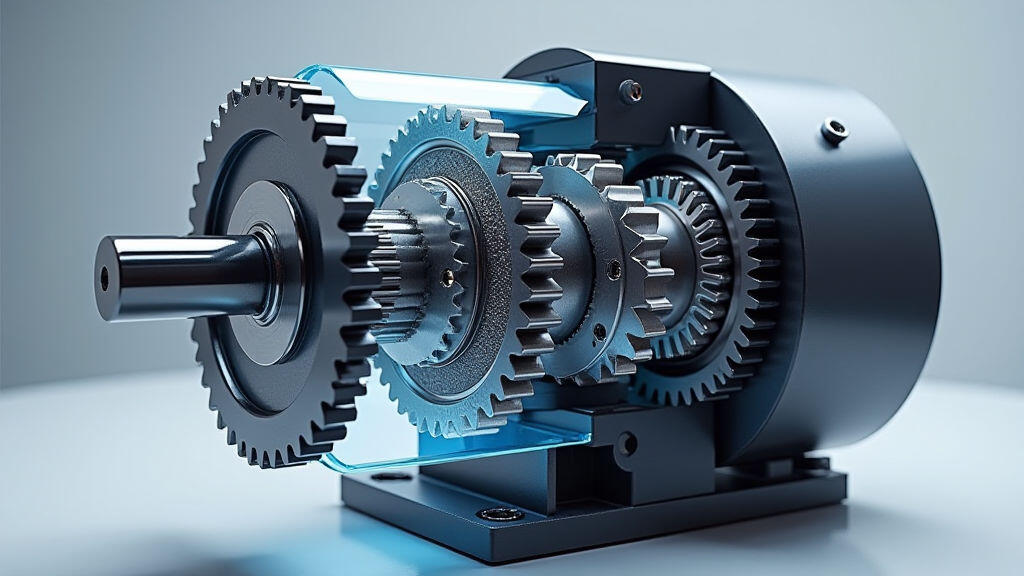

At its core, a gear motor is an electric motor integrated with a gearbox. The electric motor provides rotational power, while the gearbox acts as a critical intermediary, altering the output characteristics. Primarily, gear trains are used to reduce the motor's high speed and increase its torque. This is a crucial benefit for many applications because while electric motors excel at high-speed operation, many tasks require controlled, lower-speed, high-torque output.

The principles governing gear motors are rooted in fundamental mechanical engineering concepts. Gears, ranging from spur gears to planetary gears and worm gears, are designed to transmit rotational motion and force. The gear ratio – the ratio of the number of teeth on the driving gear to the number of teeth on the driven gear – directly determines the speed reduction (or increase) and torque amplification.

For example, a gear ratio of 10:1 means that for every 10 revolutions of the motor shaft, the output shaft rotates only once. This results in a significant increase in torque. The choice of gear type depends heavily on the application's specific requirements. Spur gears are simple and cost-effective, while planetary gear sets offer higher power density and smoother operation, particularly beneficial for high-torque applications. Worm gears are ideal for applications requiring high reduction ratios and self-locking capabilities.

Practical Applications: A Wide Spectrum of Uses

The versatility of gear motors has led to their widespread adoption across diverse sectors. Consider these key examples:

Industrial Automation: Perhaps the most prominent application is in industrial robots and automated machinery. Gear motors provide the precise motion control required for tasks such as pick-and-place operations, assembly lines, and material handling. Their ability to deliver consistent, controlled torque is essential for ensuring accuracy and repeatability.

Robotics: In the rapidly advancing field of robotics, gear motors are indispensable for powering joints, wheels, and other moving parts. From small consumer robots to large industrial arms, gear motors provide the power and precision needed for complex maneuvers. The demand for smaller, more efficient gear motors is particularly high in this area.

Medical Devices: Precision is paramount in medical equipment. Gear motors are utilized in surgical robots, infusion pumps, and other medical devices where controlled and reliable movement is critical. Miniature gear motors are often employed in these applications due to their compact size and high precision.

Consumer Electronics: Gear motors are found in a surprising number of everyday devices. Power tools, electric toothbrushes, blenders, and even some gaming controllers utilize gear motors to provide the necessary power and control for their functions.

Renewable Energy: Wind turbines and solar trackers often rely on gear motors to convert rotational energy into usable power. Gear motors provide the reliable and efficient power transmission needed to operate these systems in challenging environmental conditions.

Material Handling: Conveyor systems, automated guided vehicles (AGVs), and warehouse robots heavily rely on gear motors for moving materials efficiently. The ability to handle heavy loads and control precise movements makes gear motors ideal for these applications.

Advantages of Gear Motors Over Direct Drive Motors

While direct-drive motors (motors connected directly to the load) offer simplicity, gear motors provide several significant advantages:

Higher Torque Output: The primary benefit – significantly increased torque for a given motor size.

Speed Reduction: Allows for operation at lower, more suitable speeds for various tasks.

Improved Control: The gear train can enhance motor control by providing a more predictable and manageable output.

Compact Size: Often, a gear motor can achieve the desired torque and speed reduction in a smaller package than a direct-drive motor system.

Cost-Effective: In many applications, the added cost of the gearbox is offset by the benefits it provides, resulting in a more cost-effective overall solution.

Challenges and Future TrendsDespite their advantages, gear motors aren’t without their challenges. Gearbox efficiency can be a concern, and gear noise can be a drawback in sensitive environments. Maintenance requirements – lubrication and eventual gear replacement – also need consideration.

Future trends are focused on overcoming these limitations and further enhancing gear motor performance:

Integrated Gear Motors: Manufacturers are increasingly integrating the gearbox directly into the motor housing, reducing size and improving efficiency.

Advanced Gear Materials: The use of advanced materials like high-strength alloys and optimized gear designs is leading to improved gear efficiency and reduced noise.

Smart Gear Motors: Incorporating sensors and control systems into gear motors allows for real-time monitoring of performance and predictive maintenance.

Miniaturization: Continued efforts are focused on developing smaller, more powerful gear motors for applications in micro-robotics and other space-constrained environments.

Improved Efficiency: Research is focused on reducing friction and energy loss within the gear train to improve overall efficiency.

Conclusion: The Enduring Importance of Gear Motor Principles

Gear motors are a cornerstone of modern automation and a vital component in numerous industries. Their ability to bridge the gap between high-speed electric motors and low-speed, high-torque applications has made them indispensable. With ongoing advancements in materials, design, and control systems, gear motor technology is poised to play an even more critical role in the future. As industries embrace increased automation and strive for greater energy efficiency, the demand for sophisticated and reliable gear motor solutions will only continue to grow. The trend towards Industry 4.0 and the development of advanced robotics will significantly accelerate this growth, solidifying the enduring importance of gear motor principles in practical applications. The continuous innovation in gear motor technology is not just about incremental improvements; it's about enabling breakthroughs in automation, robotics, and beyond, fueling progress across numerous sectors.

Leave A Reply

Your email address will not be published. Required fiels are marked